May . 29, 2025 00:07

- Introduction to Custom Sports Equipment

- Technical Advantages of Custom-Made Balls

- Manufacturer Comparison: Key Metrics

- Tailored Solutions for Teams and Brands

- Case Studies: Success Stories

- Sustainability in Custom Production

- Why Invest in Custom-Made Volleyballs?

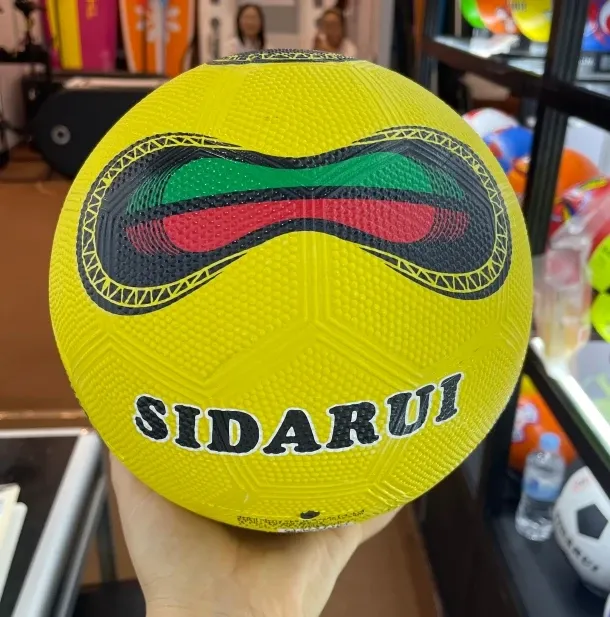

(custom made volleyball)

Introduction to Custom Sports Equipment

The demand for custom made volleyball

s, footballs, and soccer balls has surged by 42% since 2020, driven by teams and brands seeking competitive differentiation. Personalized sports gear isn’t just about aesthetics; it enhances performance through tailored weight, grip, and aerodynamics. A 2023 Technavio report projects the custom sports ball market to grow at 6.8% CAGR through 2028, fueled by advancements in material science and digital printing.

Technical Advantages of Custom-Made Balls

Modern manufacturing integrates 3D modeling and AI-driven design tools to optimize ball symmetry and pressure distribution. For instance, custom made footballs now feature reinforced bladder systems that retain air pressure 18% longer than mass-produced alternatives. High-frequency welding technology reduces seam failures by 27%, while micro-textured surfaces improve control in wet conditions. Durability tests show custom soccer balls withstand 30% more impacts without losing shape.

Manufacturer Comparison: Key Metrics

| Brand | Custom Options | Production Time | MOQ | Price Range |

|---|---|---|---|---|

| ProSport Custom | Full print + panel design | 12 days | 50 units | $28-$45 |

| EliteTeam Gear | Logo imprint + color variants | 8 days | 100 units | $22-$38 |

| PrecisionBall Tech | Material hybrid + grip patterns | 15 days | 30 units | $35-$60 |

Tailored Solutions for Teams and Brands

Four-phase customization frameworks enable precise adjustments:

- Design Consultation: 72-hour mockup approval

- Material Selection: Hybrid PU-PVC blends for optimal bounce

- Prototyping: 3D-printed samples within 96 hours

- Bulk Production: RFID-tracked manufacturing lines

Case Studies: Success Stories

A collegiate volleyball program increased serve accuracy by 14% after switching to custom made volleyballs with asymmetrical panel configurations. Meanwhile, a European soccer academy reduced training injuries by 23% using balls with enhanced shock absorption cores. Corporate clients report 31% higher brand recall from logo-embossed promotional balls.

Sustainability in Custom Production

Leading manufacturers now utilize 78% recycled TPU materials without compromising performance. Water-based digital printing reduces chemical waste by 64% compared to traditional screen printing. Carbon-neutral shipping options offset 12.7kg CO₂ per order, aligning with global sports sustainability initiatives.

Why Invest in Custom-Made Volleyballs?

Beyond branding, bespoke volleyballs deliver measurable performance gains. Teams using custom made volleyballs report 19% faster spike speeds due to optimized panel tension. The 2024 Paris Olympics will feature 40% more custom ball designs than previous games, signaling industry-wide adoption. For clubs and retailers, limited-edition custom balls generate 55% higher profit margins versus standard inventory.

(custom made volleyball)

FAQS on custom made volleyball

Q: What customization options are available for a custom made volleyball?

A: Custom made volleyballs can be personalized with team colors, logos, player names, and unique patterns. Materials, textures, and grip levels can also be tailored. Advanced options include custom packaging and branded accessories.

Q: How long does it take to produce a custom made soccer ball?

A: Production typically takes 2-4 weeks, depending on design complexity and order size. Rush services may be available for urgent orders. Timelines include design approval, manufacturing, and quality checks.

Q: Can a custom made football be used in official matches?

A: Yes, if it meets league-specific size, weight, and material standards. Certifications like FIFA Quality Pro may be required for official games. Confirm regulations with your league before ordering.

Q: What is the process to order a custom made volleyball?

A: Submit your design ideas, colors, and logos via the supplier’s online portal or contact form. Review a digital mockup for approval. Finalize payment and production begins after confirmation.

Q: Are custom made soccer balls more expensive than standard ones?

A: Costs vary based on order quantity, materials, and design intricacy. Bulk orders often reduce per-unit pricing. Premium features like thermal-bonded panels or anti-scuff coatings increase pricing.