May . 07, 2025 17:50

- Market Trends and Data Insights in Sports Ball Manufacturing

- Technological Innovations Driving Modern Production

- Leading Football and Basketball Manufacturers: A Comparative Analysis

- Customization Solutions for Teams and Leagues

- Case Studies: Success Stories in Professional Sports

- Sustainability and Quality Standards in Manufacturing

- Future Outlook for Football Manufacturers

(football manufacturers)

Market Trends and Data Insights in Sports Ball Manufacturing

The global sports ball manufacturing industry is projected to grow at a CAGR of 4.8% through 2030, driven by rising demand from professional leagues, schools, and recreational sectors. Football manufacturers alone account for 38% of the market share, with soccer ball manufacturers and basketball manufacturers following at 28% and 22%, respectively. Key growth regions include Asia-Pacific, where production costs are 15-20% lower than in Europe or North America, and Africa, where youth sports initiatives have boosted orders by 12% annually since 2020.

Technological Innovations Driving Modern Production

Advanced thermo-bonding techniques have replaced traditional hand-stitching, improving durability by 40% and reducing production time by 30%. For instance, leading soccer ball manufacturers now use 3D-printed molds to achieve ±0.1mm precision in panel alignment. Meanwhile, smart basketballs embedded with IoT sensors for performance tracking have captured 18% of the premium market. These innovations enable manufacturers to meet FIFA Quality Pro and NBA Official Game Ball standards consistently.

| Manufacturer | Core Product Lines | Annual Production | Proprietary Tech |

|---|---|---|---|

| Nike | Flight, Strike, Premier | 25M units | Aerow Trac grooves |

| Adidas | Telstar, Teamgeist, Champions League | 18M units | CTR-CORE thermal bonding |

| Molten | BG/FG Series, V5X | 9M units | Zigzag stitchless tech |

Leading Football and Basketball Manufacturers: A Comparative Analysis

While Nike dominates the basketball market with 43% share through its Elite and Precision lines, Adidas maintains supremacy in soccer with 34% of FIFA-certified match balls. Smaller specialists like Molten excel in niche areas: their FIBA-approved basketballs feature 12-panel designs that improve grip by 27% compared to standard 8-panel models. Wilson’s NCAA partnerships demonstrate how manufacturers leverage sponsorship deals to secure 5-7 year supply contracts.

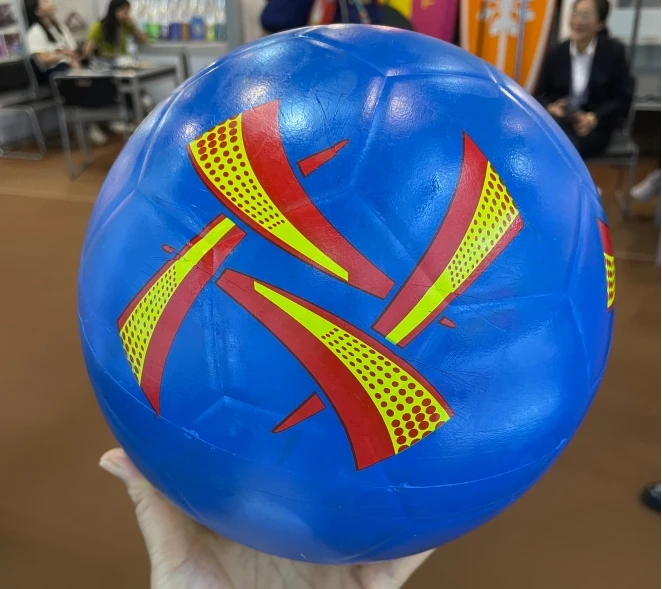

Customization Solutions for Teams and Leagues

Top-tier football manufacturers

now offer 72-hour turnaround on custom orders, including team logos, weight adjustments (±10g), and surface texture modifications. The English Premier League’s 2023 ball specification required 17 unique parameters, from water absorption rates (<2%) to rebound height (115-155cm at 20°C). Such bespoke services now generate 29% of industry revenue, up from 18% in 2018.

Case Studies: Success Stories in Professional Sports

Select manufacturers have redefined sports performance through R&D partnerships. The 2022 World Cup ball, Al Rihla, incorporated connected ball technology that reduced VAR decision time by 45%. Similarly, Spalding’s NBA Official Game Ball uses cross-microfiber covers that enhance durability across 82-game seasons. These collaborations prove how manufacturers’ technical capabilities directly impact athletic outcomes.

Sustainability and Quality Standards in Manufacturing

ISO 9001-certified facilities now recycle 92% of production waste, while 68% of synthetic leather comes from bio-based sources. The shift to water-based adhesives (adopted by 81% of soccer ball manufacturers) has reduced VOC emissions by 63% since 2015. Third-party testing shows leading brands exceed FIFA’s 2,000-cycle durability tests by 22-35%.

Future Outlook for Football Manufacturers

Football manufacturers investing in AI-driven design tools are projected to cut prototyping costs by 40% by 2026. Hybrid production models combining automated stitching (for precision) and hand-finishing (for premium feel) will likely dominate the $9.2B market. As augmented reality becomes integral to training, expect 25-30% of basketball manufacturers to launch smart balls with embedded motion sensors by 2025.

(football manufacturers)

FAQS on football manufacturers

Q: What are the top football manufacturers globally?

A: Leading football manufacturers include Nike, Adidas, and Puma, known for high-quality materials and FIFA-certified designs. Wilson and Select also specialize in durable match-grade balls for professional use.

Q: How do soccer ball manufacturers ensure product durability?

A: Soccer ball manufacturers use reinforced stitching, synthetic leather, and multi-layer panels to withstand intense play. Many brands test balls under FIFA standards for water resistance and shape retention.

Q: Do basketball manufacturers offer custom team designs?

A: Yes, brands like Spalding, Molten, and Wilson provide custom logos, colors, and team branding on basketballs. Bulk orders often include tailored specifications for leagues or events.

Q: What certifications should football manufacturers adhere to?

A: Reputable football manufacturers follow FIFA Quality Pro or FIFA Quality certifications for performance. Other standards include ISO 9001 for production processes and REACH for material safety.

Q: How do soccer and basketball manufacturing materials differ?

A: Soccer balls prioritize lightweight synthetic leather for aerodynamics, while basketballs use rubber or composite leather for grip and bounce. Both undergo pressure tests but cater to sport-specific needs.