Jul . 22, 2025 08:01

Introduction to Modern Football Technology

The global football industry has witnessed remarkable transformations, particularly in the materials and production technologies used to manufacture high-performance all football products. As FIFA standards continue to evolve, manufacturers like Hebei Starry Sports Goods Co., Ltd. are pioneering innovations in PVC football and rubber construction methods to meet the demanding requirements of modern football.

When considering football use across different environments - from professional stadiums to community pitches - the material composition becomes paramount. The shift toward pvc football construction has revolutionized the industry, offering superior durability and consistent performance. All football enthusiasts now demand balls that maintain optimal air retention and flight stability under diverse playing conditions.

Material Innovations in Football Production

The evolution from traditional leather to advanced synthetic materials represents one of the most significant advancements in all football manufacturing. Modern PVC football products utilize multi-layer constructions that optimize performance characteristics. The outer casing typically consists of polyurethane (PU) or polyvinyl chloride (PVC) with specialized treatments for water resistance and abrasion protection.

Internal components have similarly evolved, with most professional-grade footballs now featuring butyl rubber bladders that maintain air pressure 3-5 times longer than natural rubber alternatives. This technological advancement is particularly important for football use in competitive matches where consistent performance is non-negotiable. According to FIFA Quality Programme standards, approved match balls must not lose more than 15% of their initial pressure during a 72-hour period.

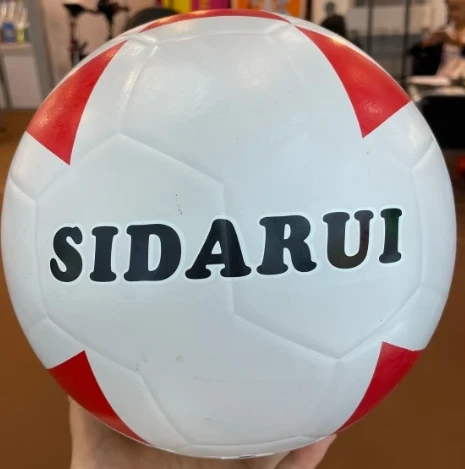

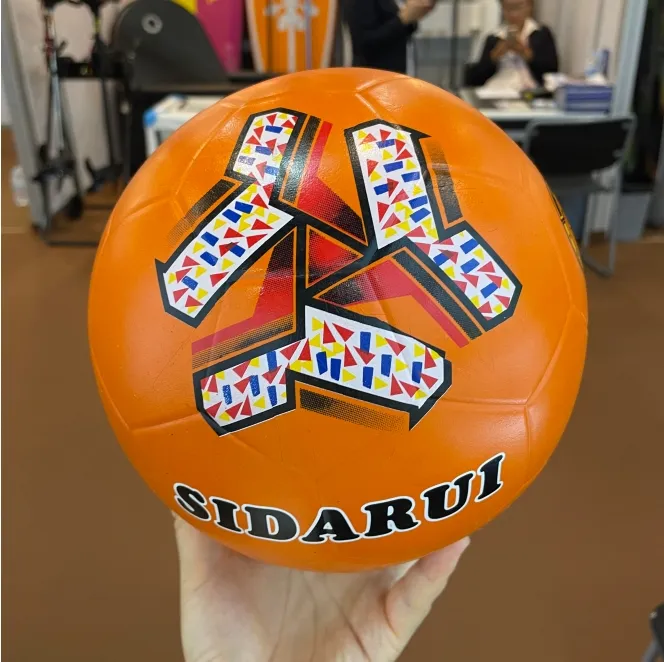

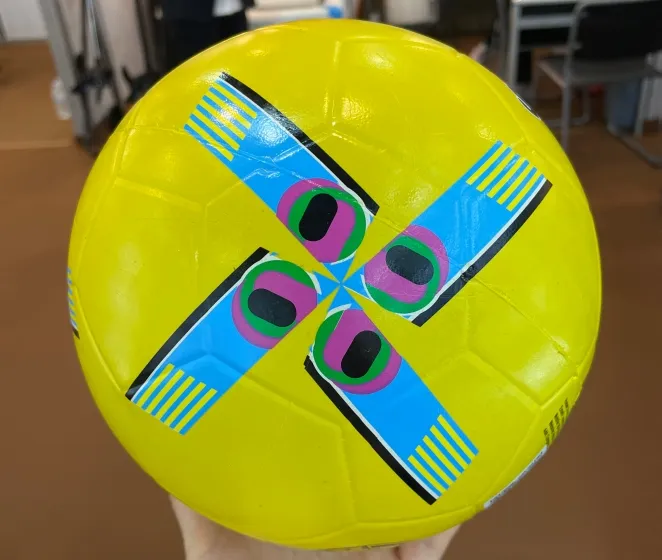

Premium Rubber Football

Our High Quality Rubber Football Ball with Customizable Logo comes in sizes 2, 3, 4, and 5 to meet diverse player needs. These soccer balls are crafted from top-grade rubber, ensuring a smooth surface that enhances ball control and reduces friction during play. The high-quality material withstands rigorous practice and competitive matches, making it the preferred choice for players seeking reliability and professional performance across all football applications.

Technical Specifications for Football Sizes

| Football Size | Circumference | Weight | Recommended Use | FIFA Standard |

|---|---|---|---|---|

| Size 5 | 27-28 inches | 410-450g | Adults & Professionals | FIFA Approved |

| Size 4 | 25-26 inches | 350-390g | Youth (12+ years) | FIFA Basic |

| Size 3 | 23-24 inches | 300-320g | Children (8-12 years) | Not regulated |

| Futsal Ball | 24.8-25.3 inches | 400-440g | Indoor/Futsal | FIFA Approved |

Global Football Manufacturing Insights

The football bulk manufacturing sector has grown exponentially to meet global demand, with production hubs strategically located near raw material sources and transportation networks. Manufacturers like Hebei Starry Sports optimize production efficiency through vertical integration, controlling all processes from material formulation to final inspection.

In the context of football use patterns, studies indicate that recreational football players replace balls every 12-18 months, while professional teams and academies implement a 3-6 month replacement cycle due to intensive usage. This drives significant demand for football bulk purchases from educational institutions and sports organizations.

Professional Football Manufacturing FAQ

PVC football offers superior water resistance, consistent performance in varied weather conditions, and enhanced durability. The material maintains its structural integrity at pressures up to 15 PSI and across temperature ranges from -10°C to 50°C. Unlike leather alternatives, PVC doesn't absorb moisture which can add up to 20% weight during wet conditions.

FIFA Quality Pro certification requires strict adherence to eight technical parameters: circumference (68.5-69.5cm), sphericity (≤1.5% difference), water absorption (≤10% weight increase), weight (420-445g), rebound (135-155cm at 2m drop), loss of pressure (≤20% over 72hrs), shape/size retention, and balance tests. Professional all football manufacturers must pass these rigorous tests annually for certification.

Modern footballs typically utilize 3-5 layer constructions. The outermost casing provides abrasion resistance and surface texture for aerodynamic properties. Intermediate layers add structure and dimensional stability. Thermal-bonded fabric layers transfer energy more efficiently than stitched alternatives, eliminating water ingress points while optimizing rebound characteristics. The innermost bladder features butyl rubber for exceptional air retention.

Industry standards require individually wrapped balls in polyethylene sleeves to prevent abrasion during transit. Bulk shipments utilize durable corrugated cartons with internal dividers, limiting each carton to 24-36 units depending on ball size. Temperature-controlled shipping is recommended for international transport to prevent material degradation from extreme temperature fluctuations exceeding 40°C.

Professional manufacturers utilize thermal transfer printing (TTP) or digital sublimation processes. TTP provides exceptional durability, with prints lasting over 100 hours of intensive play without noticeable fading. Sublimation allows full-color designs across 90% of the ball surface. Both methods meet FIFA standards requiring logos to withstand abrasion testing without degradation exceeding 10% opacity loss.

Futsal balls feature reduced bounce characteristics achieved through denser foam layers beneath the outer casing. Standard rebound heights are limited to 55-65cm from a 2m drop, compared to 135-155cm for outdoor balls. This design control enhances ball control on hardcourt surfaces. Additionally, futsal balls incorporate higher density rubber bladders maintaining pressures between 0.6-0.9 bar for optimal surface response.

Comprehensive quality systems include inflation retention testing (measuring pressure loss over 72 hours), accelerated aging tests exposing balls to UV equivalent to 6 months sunlight, dynamic water absorption tests simulating heavy rain conditions, circumference measurements with laser calipers (±0.1mm accuracy), and rebound consistency testing with computerized drop mechanisms.

Global Football Market Dynamics

The market for all football equipment continues to expand significantly, with research indicating a 7.2% CAGR (2023-2030). Growth drivers include rising youth participation programs globally, expansion of women's football leagues, and infrastructure development in emerging markets. The sports equipment segment now represents a $14.7 billion industry annually, with football bulk purchases accounting for approximately 22% of this total.

Regional preferences significantly influence manufacturing specifications. European markets prioritize FIFA-certified professional balls (68% of premium segment), while Asian and African markets show stronger demand for recreational and training balls with different football use patterns. Our PVC football range meets diverse regional requirements through adaptable manufacturing processes.