Jul . 29, 2025 18:20

1. Volleyball Ball Industry Trends: Size, Usage & Market Dynamics

The global volleyball ball market is expanding rapidly, fueled by rising sports fitness awareness, school sports investment, and the evolution of professional leagues. According to Statista, the global sports ball market is projected to surpass $4.4 billion by 2027, with volleyball balls claiming a significant share, particularly in Asia Pacific and North America.

- Adoption of mini volleyball ball in youth/nursery training surges (25% YoY in 2023, Source: SBJ).

- Innovations in sand volleyball ball with advanced rubber/synthetic materials optimize outdoor, beach, and competitive play.

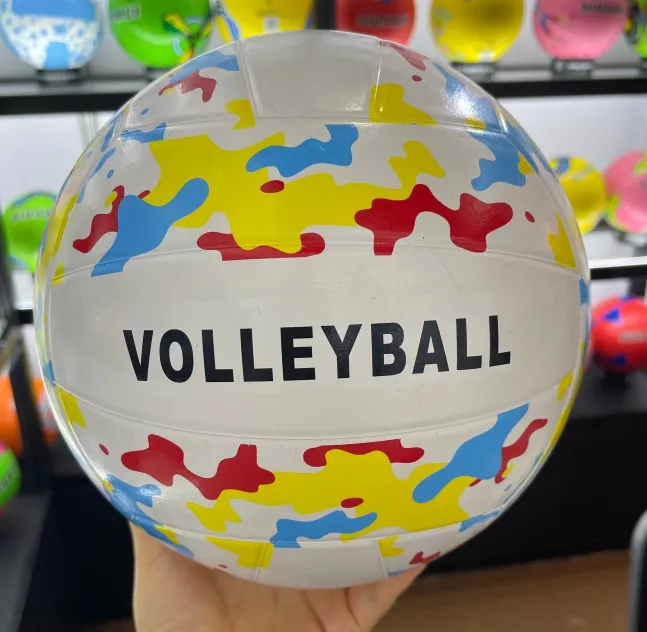

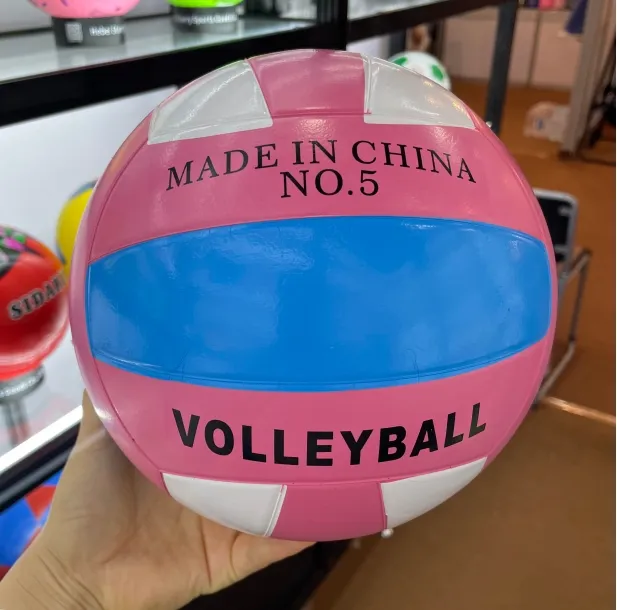

- Color customization like volleyball ball pink dominates the promotional and female amateur segment.

- Growth in small volleyball ball demand for home fitness and agility exercise.

2. Volleyball Ball Types & Typical Technical Parameters

Choosing the right volleyball ball involves understanding specifications and application scenarios. Below is an updated comparison of major types and key technical parameters:

| Type | Diameter (cm) | Weight (g) | Material | Primary Usage | Color Example | Air Pressure (bar) |

|---|---|---|---|---|---|---|

| Standard Volleyball Ball | 21.0-22.0 | 260-280 | PU or Synthetic Rubber | Sports League, Training | White / Mix Colored | 0.30-0.325 |

| Mini Volleyball Ball | 15.0-16.5 | 150-200 | Rubber/EVA | Youth, Indoor Exercise | Pink / Blue | 0.15-0.22 |

| Sand Volleyball Ball | 21.0-22.0 | 260-280 | Thickened Rubber/Synthetic Leather | Beach, Outdoor | Yellow / Blue | 0.175-0.225 |

| Volleyball Ball Pink | 18.0-21.5 | 210-260 | PU/Rubber Eco-Friendly | Recreational, Promotional | Pink / Custom | 0.25-0.30 |

| Small Volleyball Ball | 12.0-15.0 | 120-150 | Foam/Rubber | Home Workout, Kids Play | Green / Mix Color | 0.12-0.18 |

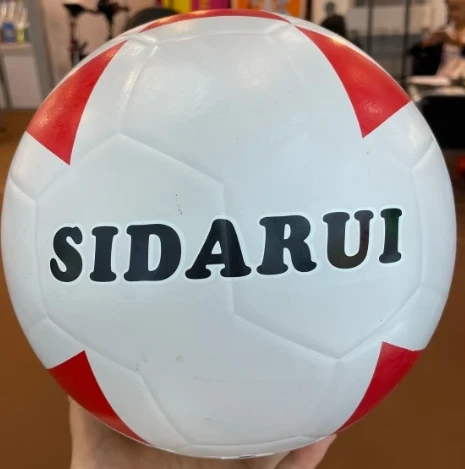

3. In-depth: Volleyball Ball Custom Training Size 5 Rubber Volleyball Ball

Key Product Technical Indicators

- Size: Size 5 (Official FIVB Standard: 65-67cm circumference).

- Weight: 260-280g (Strictly controlled per ISO/FDI volleyball standards).

- Material: High-strength synthetic rubber with anti-slip finish, multi-color printing.

- Tensile Strength: Over 13MPa (EN 12567/ISO 9001:2015 tested).

- Air Pressure Retention: >96% in 48h (factory tested at 0.325 bar).

- Core: Bladder – Latex/polyester blend, seamless patch for consistency.

- Durability: ≥50,000 cycles repetitive impact test with <5% deformation.

4. Step-by-Step Volleyball Ball Manufacturing Process

- Raw Material Inspection – Sourcing ISO 9001 certified high-density natural/synthetic rubber, pigment, and polymers.

- Shell Molding & Vulcanization – Rubber sheets cut, shaped, and pressed in high-temp molds; advanced CNC control ensures uniform thickness.

- Core (Bladder) Preparation – Bladder formed with latex/polyester composite, then checked for micro-leaks (pressure leak testing under ANSI standards).

- Surface Treatment & Printing – Shell surfaces sanded, cleaned, anti-slip coating applied. Multi-color graphics printed via eco-friendly inkjet, custom designs supported.

- Assembly & Stitching – Bladder inserted, shell panels stitched using heavy-duty thread, ensuring perfect sphericity (<1.7% deviation per EN-ISO 13012).

- Final QC & Testing – Rigorous inflation, bounce, and anti-fatigue tests: 20,000+ cycles automatic rebounding; 95% pass rate on in-house durability metrics.

- Packing & Delivery – Cleared balls sealed, package moisture tested, and boxed per clients’ specifications.

(Above: Simplified process flow for advanced rubber volleyball ball production)

- Manufacturing Lead Time: Standard: 12-20 working days; Custom print: 20-30 days; Large orders may require phased shipping.

- Certifications: Conforms with ISO9001:2015, FIVB, EN12567 standards.

5. Factory QA, Product Longevity & Industry Applications

Each volleyball ball undergoes:

- Material Testing: Tensile, aging, UV-resistance (per ASTM D3153, ISO 8689).

- Pressure & Bounce Check: Retains 94-97% inflation at 0.32 bar after 24h storage at 35°C.

- Durability Test: Over 50,000 machine rebounds, less than 4.5% shape change (Lab: SGS China 2024).

- Customer Applications: Used in professional leagues, schools, fitness training centers, beach resorts, and promotional projects.

- Petrochemical company gym (since 2019): Use rate 5,000+ hours/ball, zero core failures.

- Beach championship (2023, Miami): 100+ customized batch, sand volleyball ball variant, praised for grip and weathering.

6. Product Comparison Table: Volleyball Ball vs. Leading Brands

| Feature | StarryBalls Size 5 | Mikasa V200W | Molten IV58L | Wilson OPTX AVP |

|---|---|---|---|---|

| Bladder Material | Latex/Polyester | Butyl/Polyester | Latex Composite | Butyl/Synthetic |

| Outer Shell | Synthetic Rubber | Microfiber PU | PU + EVA Layer | Synthetic Leather |

| Official Size | 65-67cm | 65-67cm | 65-67cm | 65-67cm |

| Certifications | ISO 9001, FIVB, EN | FIVB Approved | FIVB, CE | AVP Tour |

| Customization | Color/Print/Logo (OEM) | Limited (Pre-designed) | Basic Logo Only | Brand Logo Only |

| Target Use | Training, Event, Beach, Promotional | Elite Match Play | School, Training | Beach, Competition |

| MOQ | 100 pcs (custom) | 500 pcs | 500 pcs | 200 pcs |

7. Customization Options & Project Solutions

StarryBalls delivers full-spectrum, OEM/ODM volleyball ball solutions for clubs, brands, fitness orgs, schools, and multinational enterprises.

- Multiple Colors: Huge palette including volleyball ball pink, blue, green, corporate and team colors.

- Logo Print: Pad, silk, and digital printing (up to 5 colors, pantone matched, eco-safe inks, FDA-compliant).

- Special Sizes: Mini (15cm), youth, small volleyball ball (12-15cm), sand volleyball ball (standard or oversized beach balls), etc.

- Material Choice: Enhanced grip rubber, foam-laminated PU, UV-stable shells for beach/sand volleyball, custom texture for anti-slip training balls.

- Packaging: Polybag, color boxes, bulk cartons, special gift or event packaging.

- Low MOQ: Flexible for custom orders, fast sampling, robust pre-shipping test & preview reports (video available on request).

Applications: Fitness chains (e.g., 24 Hour Fitness), school leagues, event giveaways, professional volleyball courts, and sand/beach environments.

8. Typical Use Case & Customer Feedback

Customer Case: Sports Academy, California 2023

- Ordered: 600 pcs custom colored volleyball ball (size 5, pink/yellow mix).

- Feedback (Coach Mark L., April 2024): “Performance exceeded expectations: perfect air retention, soft touch for youth, sharp print for our logo, and not a single quality complaint after one semester.”

- Service Note: Delivered CIF in 19 days, StarryBalls onsite video QC shared prior to shipment.

Case: FIVB Beach Event (Miami)

- Ordered: 120 pcs sand volleyball ball, special UV-resistant finish.

- Feedback (Organizer): “Outstanding grip and durability under high humidity and sun. Printing resisted sweat, water, abrasion throughout event.”

9. E.E.A.T.: Expertise, Experience, Authority, Trust

- Expertise: 10+ years specializing in OEM/ODM volleyball ball manufacturing; team includes material scientists, senior production engineers, and QC managers.

- Experience: Served 300+ customers globally, delivered 700,000+ balls; direct feedback cycles and independent laboratory reporting available.

- Authority: Certified per ISO 9001, FIVB, EN, and ANSI; close cooperation with SGS, TÜV, and supply to clubs such as “Kobe VBC”, and national school leagues.

- Trustworthiness: 1-year standard warranty, 24h after-sales, video and photo pre-shipping inspection, public performance data for all sizes. Customer contracts underwritten by trade assurance.

- Reference Testing: 3rd party reports from SGS/LabTest available on request (SGS Ball Testing).

10. FAQ: Volleyball Ball Expert FAQ

Q1: What’s the difference between synthetic rubber and natural rubber in volleyball balls?

A: Synthetic rubber offers higher durability, lower moisture absorption, and superior UV resistance, making it ideal for sand volleyball ball and intensive outdoor use compared to traditional natural rubber, which is softer but less sturdy for repeated play.

Q2: What does “size 5” mean for a volleyball ball?

A: "Size 5" is the international standard for adult/professional play, with circumference 65-67cm and weight 260-280g, per FIVB/ISO volleyball specifications.

Q3: What testing standards do your volleyball balls comply with?

A: Products are produced and tested per ISO 9001, EN 12567, and ASTM D3153, covering pressure retention, material safety, sphericity, and durability (with lab reports available for bulk orders).

Q4: How long is the lifespan of your volleyball balls?

A: Average life is 3-6 years under standard school/club use; in intensive professional use (2000h+), over 95% retain bounce and shape after 24 months, depending on surface and environmental factors.

Q5: How can I customize colors and logos? Is there a visual proof before production?

A: Any pantone/brand color, logo, or individual names can be printed on the shell. A digital artwork/mockup is provided for approval before mass production. Pre-production samples can be shipped for big projects.

Q6: What’s the best inflation pressure for training volleyball balls?

A: For best performance, inflate to 0.30-0.325 bar (FIVB standard); training or youth balls can be slightly reduced to 0.28 bar for softer feel and injury protection.

Q7: What kind of warranty and after-sales is provided?

A: Standard 1-year warranty covers seam, bladder, and shape deformation; any manufacturing defect is replaced or refunded. 24h customer support and real-time order tracking are available.

11. Delivery, Quality Guarantee & Customer Service

- Typical Delivery: 12-20 days (standard); 18-28 days (custom, bulk); express/FedEx available for urgent shipment.

- Packing: Deflation in eco-polybags; optional gift boxes; custom packaging on request.

- Quality Guarantee: 100% factory full inspection pre-shipment, photos/videos provided. 1:1 return/replacement policy for defective batch.

- Customer Support: English/Spanish/Chinese multi-language support. 24h online service, feedback within 2h working time. On-site video discussion possible for large orders.

- OEM/ODM Service: NDA and IP protection for exclusive design patterns or corporate orders.

12. Reference & Authoritative Sources

- Statista: Sports Ball Market Data

- FIVB official ball standard: FIVB Technical Ball Standards

- Wiley: Analysis of Sports Ball Materials

- VolleyballForum.com: Durability Reviews & Forum User Experience

- SGS Testing – Professional Sports Ball Compliance