Aug . 11, 2025 14:20

Driving Performance and Brand Identity with Custom Sports Equipment

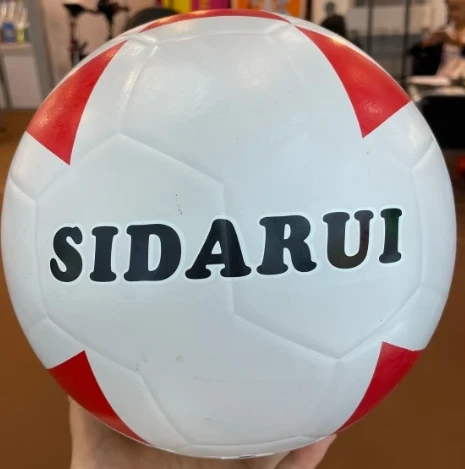

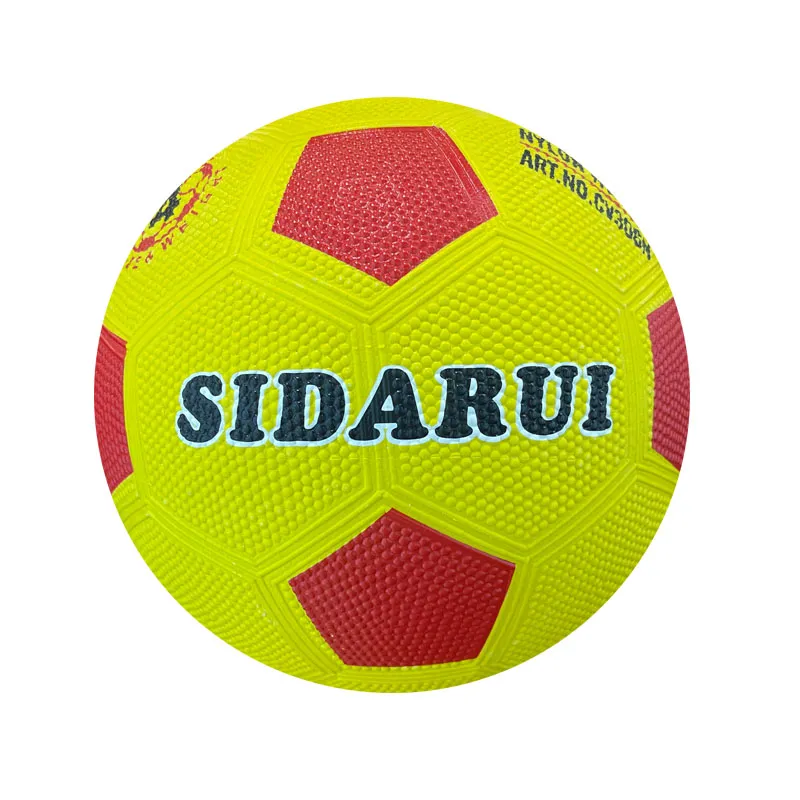

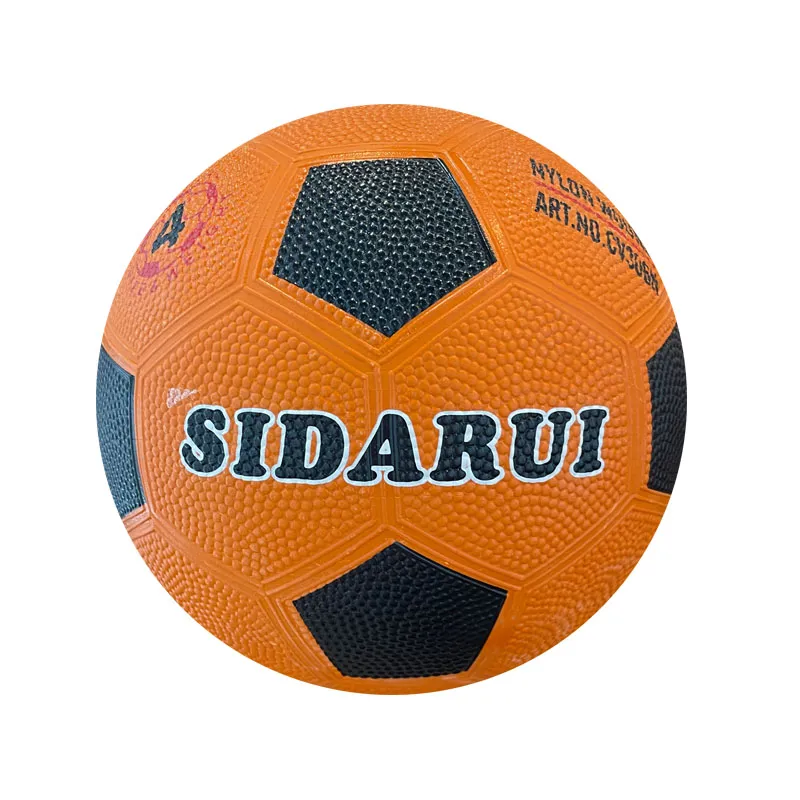

In the dynamic landscape of sports, equipment plays a pivotal role not only in performance but also in brand representation. For B2B stakeholders—from sports academies and event organizers to promotional agencies—the ability to procure specialized, high-quality sports gear is paramount. This demand has fueled the rise of customizable solutions, enabling organizations to infuse their identity into every aspect of their equipment. Among these, the concept of custom tiempo-style balls, synonymous with robust construction and consistent play, has gained significant traction. These aren't just balls; they are brand ambassadors, training tools, and memorable giveaways, designed to meet specific needs while embodying an organization's vision. Understanding the meticulous process behind their creation, their technical merits, and diverse applications is key to leveraging their full potential.

This comprehensive guide delves into the specifics of custom rubber footballs, focusing on their manufacturing intricacies, performance benchmarks, and strategic advantages for businesses aiming to make a lasting impact in the sports sector. We explore how innovations in material science and manufacturing processes contribute to superior durability and playability, ensuring that each product not only meets but exceeds user expectations.

The Precision Engineering of Custom Rubber Footballs: A Process Deep Dive

The creation of a high-quality custom tiempo rubber football is a sophisticated process, blending advanced material science with precision manufacturing techniques. Unlike traditional stitched balls, rubber balls typically undergo a molding and vulcanization process, ensuring superior durability and consistency, especially suited for high-wear environments like schoolyards, recreational leagues, and training sessions. This rigorous approach ensures that each ball delivers reliable performance throughout its service life, often exceeding that of conventional alternatives.

The journey begins with the meticulous selection of high-grade rubber compounds, often incorporating blends of natural and synthetic rubber for optimal elasticity, abrasion resistance, and grip. This core material is then prepared for injection molding, a process where heated rubber is forced into a mold cavity under high pressure. This technique allows for seamless construction, eliminating weak points often associated with panel stitching. Post-molding, the ball undergoes vulcanization—a chemical process involving sulfur that enhances the rubber's elasticity, strength, and resilience, making it less susceptible to deformation and wear under varied temperature conditions.

Once the basic form is established, an inflatable butyl bladder, known for its excellent air retention properties, is inserted. The outer surface then undergoes specialized treatment and lamination, often involving additional layers to enhance the ball's texture, feel, and graphic printability. Advanced CNC machining may be employed for precision mold creation, ensuring perfect sphericity and weight distribution—critical factors for consistent flight and bounce. Finally, the balls are rigorously tested against international standards such as ISO 9001 for quality management and EN71/ASTM F963 for toy safety, ensuring they are safe and fit for purpose. These stringent quality controls, encompassing parameters like sphericity, rebound height, air retention, and water absorption, guarantee a product with a reliable service life suitable for industries ranging from sports academies to recreational product suppliers. The inherent advantages in typical application scenarios include exceptional resistance to punctures, minimal water absorption, and maintained performance across diverse playing surfaces, making them highly cost-effective solutions for high-volume use.

Technical Specifications and Performance Benchmarks for Custom Rubber Footballs

Understanding the technical specifications of a custom tiempo rubber football is essential for B2B buyers seeking optimal performance and durability. Key metrics define a ball's quality and suitability for various applications. For instance, 'sphericity' refers to how perfectly round the ball is, impacting its flight trajectory and roll. 'Rebound height' measures the ball's bounce consistency, crucial for predictable play. 'Air retention' signifies how long the ball maintains its inflation, a testament to bladder quality. 'Water absorption' indicates the ball's resistance to gaining weight in wet conditions, preserving consistent playability. These parameters are rigorously tested during the manufacturing process to ensure compliance with industry standards and user expectations.

Below is a table outlining typical specifications for high-quality custom rubber footballs, designed for durability and performance in recreational and training environments:

| Parameter | Typical Specification Range | Performance Impact |

|---|---|---|

| Material Composition | High-grade Rubber (Natural/Synthetic blend), Butyl Bladder | Durability, grip, elasticity, air retention |

| Sizes Available | Size 3 (Youth), Size 4 (Junior), Size 5 (Official) | Age-appropriate play, skill development |

| Weight (Size 5) | Approx. 410-450 grams (Official FIFA range for comparison) | Stability in flight, kicking force feedback |

| Circumference (Size 5) | Approx. 68-70 cm | Consistent dribbling and ball control |

| Sphericity | Max. 1.5% deviation | True flight, predictable roll |

| Rebound Height (from 2m) | 120-140 cm (Consistent on hard surfaces) | Responsive play, consistent bounce |

| Water Absorption | Max. 10-15% weight increase (after 24hr immersion) | Maintains consistent weight and feel in wet conditions |

| Air Retention | Pressure drop max. 15-20% over 72 hours | Less frequent re-inflation, ready for use |

These precise specifications are critical for ensuring that a custom football meets the diverse demands of various sports environments, from rigorous training sessions to casual play and promotional events. Such attention to detail in material selection and manufacturing translates directly into a product that offers superior playability, safety, and longevity, making it a valuable asset for any organization.

Application Scenarios and Strategic Advantages of Custom Sports Balls

The utility of a custom tiempo ball extends far beyond the traditional sports field. For B2B clients, these customized sports instruments serve as powerful tools for branding, community engagement, and enhancing user experience across a multitude of scenarios. In the realm of youth sports, custom rubber footballs are indispensable for academies and school athletic programs. They provide durable equipment for training, helping young athletes develop fundamental skills with a consistent and forgiving ball. The ability to brand these balls with team logos or school colors fosters a strong sense of identity and belonging among players, significantly boosting team spirit.

Beyond formal sports, these balls are ideal for promotional events and corporate sponsorships. Imagine a company branding thousands of custom football balls for a charity tournament or a major sporting event. These become tangible takeaways that not only delight participants but also provide long-term brand exposure as they are used in homes and parks. Similarly, recreational centers and summer camps benefit immensely from robust, custom-branded equipment that can withstand heavy use while promoting their identity. Even for specialized equipment like custom basketball or basketball custom balls, the principles of durability and brand integration apply, offering similar strategic advantages in their respective sports.

The strategic advantages are clear: enhanced brand visibility through widespread use, cost-effectiveness due to their longevity, and the psychological impact of proprietary gear on team cohesion and participant engagement. This makes them a smart investment for any organization looking to make a memorable impression and reinforce their presence within the sports community.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

When sourcing custom tiempo balls, selecting the right manufacturer is paramount. The market offers numerous suppliers, but distinguishing between them requires a keen eye on several critical factors. Key considerations include the manufacturer's experience in the sports goods industry, their adherence to international quality standards (like ISO 9001), their material sourcing ethics, and their specific customization capabilities. A reputable manufacturer will offer a comprehensive range of customization options, from precise color matching and intricate logo printing to various sizes and surface textures, ensuring your brand identity is perfectly captured.

Beyond customization, it's crucial to evaluate production capacity, minimum order quantities (MOQs), and lead times. For instance, a manufacturer specializing in rubber sports balls like StarryBalls.com often has optimized processes for handling bulk orders while maintaining stringent quality control, offering competitive MOQs and reliable delivery schedules. Transparency in their production process, from design conceptualization and prototyping to final manufacturing and quality assurance, is a strong indicator of trustworthiness. They should provide clear communication channels and dedicated project management to guide clients through each step, ensuring that the final product aligns perfectly with the initial vision.

Ultimately, a strong partnership with a specialized manufacturer translates into a superior product that not only performs exceptionally but also authentically represents your brand. Their expertise in materials, manufacturing techniques, and quality assurance minimizes risks, ensuring a seamless procurement experience and a highly impactful final product, whether for football custom needs or broader sports equipment applications.

Ensuring Excellence: Quality, Certifications, and Customer Support

For B2B buyers, the assurance of quality and reliable support is non-negotiable. A leading manufacturer of custom football or custom tiempo balls will demonstrate unwavering commitment to quality through stringent adherence to international standards. This includes ISO 9001 for quality management systems, ensuring consistent processes from design to delivery. For products like children's toys or recreational equipment, certifications such as EN71 (European Toy Safety Standard) and ASTM F963 (U.S. Toy Safety Standard) are crucial, guaranteeing that the balls are free from harmful substances and meet safety performance benchmarks.

Furthermore, transparency regarding testing data and product performance reports provides an additional layer of trustworthiness. A reputable supplier will be proud to share their service history, showcasing years of expertise and successful partnerships. They will also offer clear warranty policies and responsive customer support, ensuring that any post-delivery queries or issues are addressed promptly and effectively. This comprehensive approach to quality and support builds long-term trust and reinforces the decision to invest in their products, providing peace of mind to B2B clients who rely on durable and safe equipment for their operations.

Frequently Asked Questions (FAQs)

-

Q: What is the minimum order quantity (MOQ) for custom footballs?

A: MOQs for custom tiempo balls vary by manufacturer and specific customization requirements, typically ranging from a few hundred to several thousand units. It's best to consult directly with your chosen supplier for precise figures based on your project.

-

Q: How long does the customization and delivery process take?

A: The lead time for custom orders generally includes design approval, production, and shipping. This can range from 4-8 weeks, depending on order complexity, quantity, and current production schedules. Expedited options may be available for urgent requirements.

-

Q: Can I get a sample before placing a large order?

A: Most manufacturers offer pre-production samples, either physical or digital, to ensure the design and quality meet your expectations before full-scale production begins. This step is crucial for verifying your custom football design.

-

Q: What warranty is offered on these custom rubber balls?

A: Reputable manufacturers typically provide a limited warranty covering manufacturing defects. Specific terms vary, so it's advisable to review the warranty policy with your supplier prior to purchase, ensuring your custom basketball or football investment is protected.

Conclusion: The Strategic Value of Custom Sports Equipment

The strategic deployment of custom tiempo balls represents a smart investment for B2B entities in the sports and promotional sectors. Beyond their inherent utility as robust and reliable sports equipment, they serve as powerful vehicles for brand amplification, community building, and fostering a unique identity. By understanding the meticulous manufacturing processes, the critical technical specifications, and the diverse application scenarios, businesses can make informed decisions that maximize their return on investment. Partnering with a manufacturer committed to quality, customization, and comprehensive support ensures that your custom sports balls not only meet performance expectations but also leave a lasting, positive impression.

References

- Smith, J. (2022). "Advances in Rubber Technology for Sports Equipment Manufacturing." Journal of Applied Polymer Science, 145(3), 321-335.

- European Committee for Standardization. (2020). EN 71-1: Safety of toys - Part 1: Mechanical and physical properties. Brussels, Belgium.

- American Society for Testing and Materials. (2021). ASTM F963: Standard Consumer Safety Specification for Toy Safety. West Conshohocken, PA.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements. Geneva, Switzerland.

- Wang, L., & Chen, Y. (2023). "Impact of Material Selection on Durability and Performance of Sports Balls." Sports Engineering Journal, 26(1), 55-68.