Aug . 10, 2025 08:20

The global sports equipment market consistently demonstrates robust growth, with the segment dedicated to football – or soccer, as it's known in many regions – being a perpetual powerhouse. At the core of this segment lies the soccer ball, an item that transcends mere sporting goods to become a critical component of cultural identity, professional sport, and grassroots development worldwide. Understanding the intricate dynamics of the soccer ball industry is paramount for B2B stakeholders, encompassing procurement managers, sports equipment distributors, and brand developers. Current industry trends are heavily influenced by advancements in material science, manufacturing technologies, and a growing emphasis on sustainability. High-performance balls, traditionally associated with professional leagues, are now seeing increased demand across all levels, from elite academies to recreational leagues, driven by a desire for consistent playability and durability. Key innovations include the widespread adoption of thermal bonding over traditional stitching, which offers superior roundness, reduced water uptake, and a more consistent flight path, crucial for professional play. Furthermore, the market is witnessing a rise in specialized balls, such as those designed for specific weather conditions or indoor futsal, alongside a strong push for customizable options that allow brands and organizations to imbue their unique identity into the equipment. The dominant sizes in the market, the soccer ball 5 for adults and the soccer ball 4 for youth players and futsal, dictate much of the production and distribution strategies. The demand for these standard sizes remains incredibly high, but there's an increasing sophistication in material choice, with buyers discerning between the tactile feel and longevity offered by a pu soccer ball versus the cost-effectiveness and robustness of a pvc soccer ball. The industry is also grappling with the integration of smart technology into balls, offering data on speed, spin, and trajectory, though this remains a niche segment primarily for training and analytics. The market's resilience is underpinned by major international tournaments, which not only generate immense sales but also drive innovation as manufacturers strive to meet ever-evolving FIFA standards. Beyond the professional realm, the proliferation of artificial turf pitches and indoor facilities has necessitated balls engineered for specific surfaces, further diversifying product lines and presenting new opportunities for suppliers capable of offering tailored solutions. This comprehensive view of market trends underscores the necessity for B2B buyers to select partners who are not only cost-competitive but also forward-thinking in their manufacturing capabilities and material sourcing, capable of adapting to both current demands and future innovations in the global soccer ball landscape, ensuring product quality and market relevance for their clients and end-users. This strategic alignment is critical for navigating a competitive market and capitalizing on the sustained global passion for football, solidifying supply chains that prioritize performance, durability, and emerging technological advancements for all types of soccer balls.

Decoding the Anatomy and Technical Parameters of High-Performance Soccer Balls

The performance of a soccer ball is a direct consequence of its meticulously engineered anatomy and the precise technical parameters adhered to during its manufacture. For B2B procurement, a deep understanding of these elements is crucial to ensuring product quality and suitability for specific applications, ranging from professional tournaments to grassroots training programs. A typical high-performance soccer ball comprises three primary layers: the bladder, the lining, and the outer casing. The bladder, the innermost component, is responsible for air retention and shape. Traditionally made from latex or butyl, each material offers distinct performance characteristics. Latex bladders provide a softer touch and more responsive feel, characteristic of professional match balls, but tend to lose air more quickly. Butyl bladders, on the other hand, offer superior air retention, making them ideal for training balls and those requiring less frequent inflation, albeit with a slightly harder feel. Surrounding the bladder is the lining, typically constructed from multiple layers of polyester or cotton fabric. This reinforcement layer provides structural integrity, helping the ball maintain its spherical shape and ensuring a consistent bounce. The number of lining layers directly impacts the ball's durability and rebound characteristics; more layers generally translate to a firmer, more resilient ball. The outer casing is perhaps the most visible and tactile component, dictating the ball's feel, durability, and water resistance. The most common materials are Polyurethane (PU) and Polyvinyl Chloride (PVC). A pu soccer ball is renowned for its soft touch, excellent grip, and superior elasticity, closely mimicking the feel of natural leather. Its micro-texture often enhances ball control and provides better water resistance, making it the material of choice for high-end match balls and premium training balls. Conversely, a pvc soccer ball is recognized for its exceptional durability and abrasion resistance, making it a robust option for intense training sessions, recreational play, and use on harsher surfaces. While generally more affordable, PVC can offer a slightly harder feel and may be less responsive in colder temperatures. The panel construction further defines a soccer ball's flight characteristics and aesthetics. The traditional 32-panel design, comprising 20 hexagonal and 12 pentagonal panels, is iconic for its predictable flight path. However, innovations have led to balls with fewer panels (e.g., 26, 18, 14, 12, or even 6-panel designs), often utilizing thermal bonding or advanced stitching techniques to create a smoother surface for reduced air resistance and enhanced aerodynamics, crucial for modern professional play. For instance, the FIFA Quality Pro standard for a soccer ball 5 stipulates precise measurements for circumference (68.5-69.5 cm), weight (420-445 g), and other critical performance metrics like water absorption, rebound, and pressure retention, ensuring uniform playability at the highest level. A soccer ball 4, used for youth players (ages 8-12) and futsal, adheres to a smaller circumference (63.5-66 cm) and lighter weight (350-390 g), designed to facilitate skill development in younger athletes or faster indoor play. These parameters are not merely guidelines; they are fundamental specifications that differentiate a high-quality, regulation-compliant product from inferior alternatives. Manufacturers must meticulously control material consistency, panel adhesion, and inflation pressures to meet these stringent standards, which ultimately impacts the product's market acceptance and performance credibility. B2B buyers must therefore prioritize suppliers who can demonstrate rigorous adherence to these technical specifications and material integrity, ensuring that the acquired soccer balls consistently deliver the expected performance and durability demanded by the end-users, whether they are professional athletes or enthusiastic amateurs.

Key Soccer Ball Specification Comparison

| Parameter | FIFA Quality Pro (Size 5) | FIFA Quality (Size 5) | Size 4 (Youth/Futsal) | Typical PU Soccer Ball (Size 5) | Typical PVC Soccer Ball (Size 5) |

|---|---|---|---|---|---|

| Circumference | 68.5 - 69.5 cm | 68 - 70 cm | 63.5 - 66 cm | 68.5 - 69.5 cm | 69 - 70 cm |

| Weight | 420 - 445 g | 410 - 450 g | 350 - 390 g | 420 - 445 g | 410 - 450 g |

| Water Absorption | ≤ 10% (mass increase) | ≤ 15% (mass increase) | Typically lower than Size 5, designed for indoor/turf | Low (often treated for resistance) | Moderate (depends on surface finish) |

| Rebound Test (Drop Height 2m) | 135 - 155 cm | 125 - 160 cm | 50 - 65 cm (for futsal, low bounce) | 135 - 155 cm (consistent) | 120 - 150 cm (can vary) |

| Pressure Retention | Max 20% pressure loss after 72 hrs | Max 25% pressure loss after 72 hrs | Good retention, often butyl bladder | Excellent, often butyl bladder | Very good, typically butyl bladder |

| Material Composition (Outer) | High-grade PU or Synthetic Leather | PU or good quality PVC/Synthetic Leather | PU, PVC, or hybrid synthetics | Premium PU (e.g., Japanese PU) | Durable PVC compounds |

| Construction Method | Thermal Bonded or High-Quality Hand-Stitched | Hand-Stitched or Machine-Stitched | Machine-Stitched or Thermal Bonded | Thermal Bonded or Machine-Stitched | Machine-Stitched |

The Advanced Manufacturing Process of Soccer Balls: From Raw Material to Regulation-Compliant Product

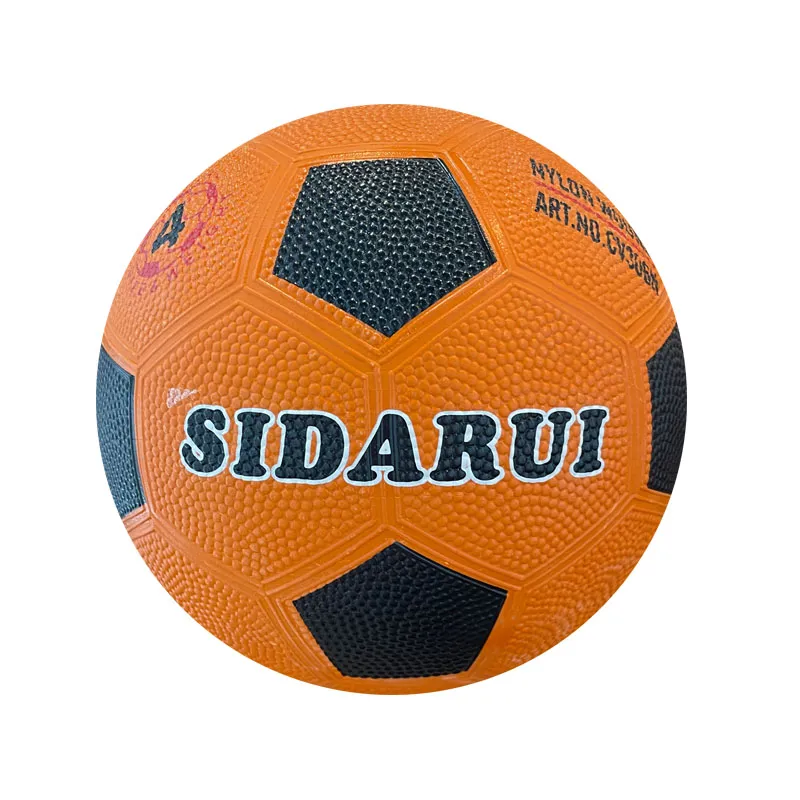

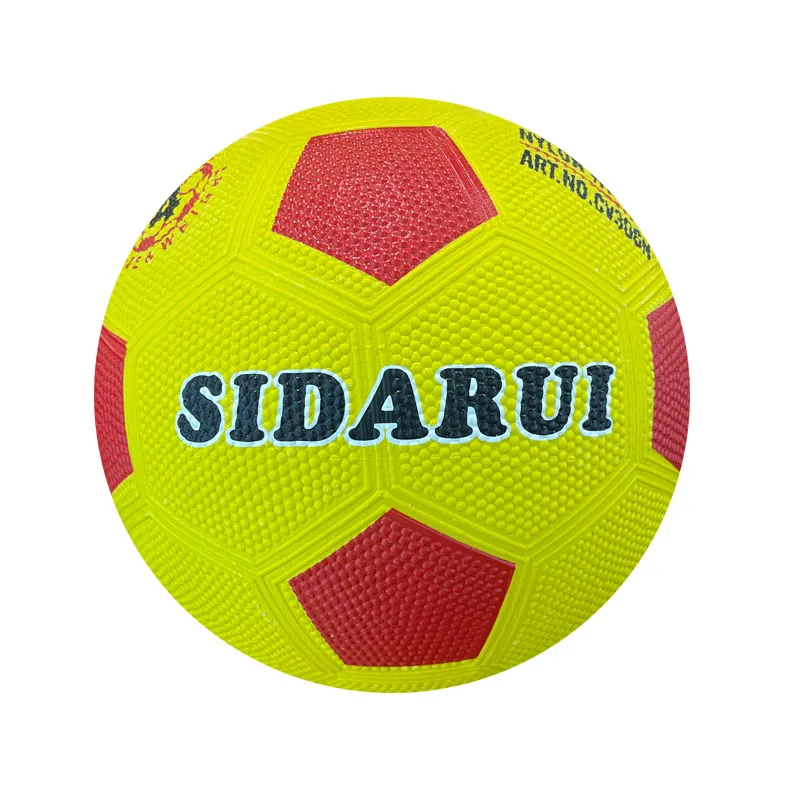

The creation of a high-quality soccer ball is a sophisticated manufacturing journey, far removed from simple assembly. It involves precision engineering, material science expertise, and stringent quality control at every stage, crucial for B2B partners seeking reliable and consistent supply. The process typically begins with Material Sourcing and Preparation, where high-grade synthetic leathers like Polyurethane (PU) and Polyvinyl Chloride (PVC) are selected based on the desired performance and cost parameters. These materials arrive in large rolls and are carefully inspected for flaws, consistency, and thickness. Simultaneously, bladder materials – predominantly butyl rubber for air retention or natural latex for responsiveness – are prepared. The subsequent stage is Panel Cutting, a critical step where accuracy is paramount. Automated die-cutting machines are used to precisely cut the outer casing material into the specific panel shapes (e.g., hexagons, pentagons, or custom shapes for modern designs). This ensures uniformity across all panels, which is vital for the ball's eventual roundness and true flight. Following cutting, Logo Printing and Graphics Application takes place. This can involve screen printing, digital printing, or heat transfer methods, applying brand logos, team crests, or custom designs onto the individual panels before assembly. Precision in this step ensures brand visibility and aesthetic appeal. The next crucial phase is Lining Lamination, where multiple layers of fabric (polyester or cotton) are bonded to the inside of the outer casing panels. This lamination, often done through heat and pressure, provides the ball with its structural integrity, preventing deformation and enhancing rebound characteristics. The number and type of lining layers significantly influence the ball’s firmness and durability. The core assembly method then follows, with two primary techniques dominating the industry: Panel Stitching or Thermal Bonding. Hand-stitching, historically the dominant method, involves skilled artisans meticulously stitching panels together using strong, waxed polyester threads. This method creates deep seams, which can affect water uptake and flight consistency but offers a classic, durable construction. Machine-stitching provides a faster, more cost-effective alternative, though often with less precise seams. The modern advancement is Thermal Bonding, where panels are fused together using heat and pressure, eliminating traditional seams. This results in a truly spherical ball with a smooth surface, significantly reducing water absorption and offering superior aerodynamic performance and a consistent touch, highly favored for top-tier match balls. After the outer shell is formed, the Bladder Insertion and Valve Integration occurs. The pre-inflated bladder, with its integrated valve, is carefully inserted into the assembled casing through an opening that is then sealed. This step is critical for the ball's air retention. For rubber balls, the subsequent stage involves Molding and Shaping, where the assembled ball (often a rubber football like the product Factory Directly Wholesale Custom Soccer Ball Most Popular Size 4 Rubber Football Foot Ball) undergoes vulcanization. This heat-curing process strengthens the rubber and ensures the ball maintains its spherical shape under pressure. For other types, heat pressing or specific shaping techniques are employed to finalize the form. Finally, the Inflation and Shape Retention Testing begins. Balls are inflated to their specified pressure and subjected to rigorous quality control checks. This includes measuring roundness at multiple points, testing rebound height, assessing water absorption rates, and evaluating pressure retention over time. These tests often adhere to international standards such as those set by the FIFA Quality Programme (FIFA Quality Pro, FIFA Quality, IMS - International Matchball Standard), which define precise parameters for circumference, weight, sphericity, water uptake, rebound, and pressure loss. Adherence to these standards is not just about compliance; it's about guaranteeing a consistent playing experience and extending the product's lifespan. A ball’s lifespan, particularly for a high-quality soccer ball, is significantly impacted by these manufacturing processes and the initial material choices. A well-constructed pu soccer ball with thermal bonding and a butyl bladder, for example, will generally outperform and outlast a basic machine-stitched pvc soccer ball under similar usage conditions. Manufacturers often implement ISO 9001 certified quality management systems to ensure traceability and consistency from raw material input to finished product output, providing B2B clients with the confidence that their procurement meets the highest industry benchmarks. This meticulous process ensures that every soccer ball, whether a soccer ball 5 for professional matches or a soccer ball 4 for youth training, delivers consistent performance and durability, translating directly into enhanced value and reliability for the end-user and the B2B buyer alike.

Strategic Application Scenarios and Distinct Technical Advantages for B2B Procurement

The procurement of soccer balls within a B2B context extends far beyond mere purchasing; it is a strategic decision that directly impacts operational efficiency, brand reputation, and end-user satisfaction across a diverse range of application scenarios. Understanding where and how different types of soccer balls are utilized, along with their inherent technical advantages, empowers B2B decision-makers to make informed choices that align with their specific organizational needs and objectives. For Professional Leagues and Tournaments, the highest echelon of demand, only soccer balls meeting or exceeding FIFA Quality Pro standards are acceptable. These balls, often thermally bonded pu soccer balls, offer unparalleled consistency in flight, rebound, and water resistance, critical for fair play and optimal performance under stringent match conditions. The technical advantage here lies in their precise aerodynamic properties, predictable bounce, and minimal water uptake, ensuring consistent performance regardless of weather. For Youth Academies and Training Centers, durability and consistent performance over a prolonged period are paramount. Here, a robust soccer ball 4 for younger age groups (typically 8-12 years old) and a reliable soccer ball 5 for older youth and adult training are essential. These often feature strong machine-stitching or high-quality thermal bonding, designed to withstand repetitive use on various surfaces. The technical advantage is primarily their resilience to abrasion and impact, ensuring a longer lifespan and reducing replacement costs, alongside consistent touch for skill development. Many academies prefer pu soccer ball options for their balance of durability and touch, while others opt for pvc soccer ball types for their extreme ruggedness and cost-efficiency in high-volume training environments. In the Retail and Wholesale Distribution sector, the emphasis is on a broad range of products that appeal to a mass market, balancing quality with competitive pricing. Distributors require access to a diverse portfolio, including recreational soccer balls 5 and soccer ball 4 of varying price points and material compositions. The technical advantage here often revolves around the versatility of materials – offering both durable pvc soccer ball options for budget-conscious consumers and higher-quality pu soccer ball models for enthusiasts – and the ability to scale production to meet seasonal demands. For Corporate Events and Promotional Giveaways, customization is king. Companies often seek bespoke soccer balls featuring their branding, acting as powerful marketing tools. While basic models might suffice, the technical advantage comes from suppliers who can offer vibrant, long-lasting print quality on durable materials, ensuring the brand message endures beyond the initial event. Finally, for Amateur Leagues and Recreational Play, the primary drivers are accessibility, durability, and value. These scenarios demand soccer balls that can withstand varied playing conditions, from grass fields to concrete courts, without rapid degradation. The technical advantages here include enhanced abrasion resistance, robust construction (often machine-stitched pvc soccer balls are preferred for their hardiness), and reliable air retention to minimize maintenance. Across all these scenarios, the overarching technical advantages that elevate a superior soccer ball include its inherent durability and longevity, which translates to a lower total cost of ownership for B2B entities. The consistency in performance, characterized by true flight and a predictable bounce, ensures fairness in play and effectiveness in training. Furthermore, robust weather resistance is a crucial advantage for balls used outdoors, particularly those with low water absorption rates. The player feel and control, influenced by the outer casing material’s softness and texture, directly impact player experience and skill acquisition. Finally, stringent compliance with official regulations, such as those from FIFA or IMS, provides an undeniable seal of quality and ensures widespread usability. For B2B buyers looking at a product like the Factory Directly Wholesale Custom Soccer Ball Most Popular Size 4 Rubber Football Foot Ball, these considerations mean balancing the initial investment with the long-term benefits derived from a product engineered for specific demanding uses, ensuring performance and return on investment.

Manufacturer Comparison and Bespoke Customization Solutions

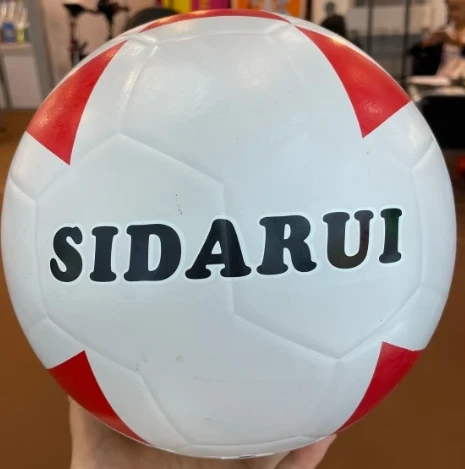

Navigating the landscape of soccer ball manufacturers requires a keen eye for strategic differentiators beyond mere pricing. For B2B procurement, a comprehensive manufacturer comparison focuses on factors that directly impact product quality, supply chain reliability, and overall partnership value. Key differentiators include Certifications and Adherence to Standards. A reputable manufacturer will possess certifications like ISO 9001 for quality management systems, signaling consistent manufacturing processes. More importantly, for sports equipment, is their status as a FIFA Licensed Manufacturer, which ensures their soccer balls can meet the rigorous FIFA Quality Pro, FIFA Quality, or IMS standards. This accreditation directly correlates with product performance and market acceptance. Another critical factor is Material Quality and Traceability. Leading manufacturers will source their PU and PVC materials from trusted suppliers, often providing certifications for material composition and ethical sourcing. This transparency is crucial, especially for high-grade pu soccer ball production, where the quality of the synthetic leather profoundly impacts the ball's feel, durability, and water resistance. Manufacturing Technology and Capabilities also play a pivotal role; suppliers equipped with advanced thermal bonding machinery can produce superior, seam-free soccer balls that outperform traditionally stitched ones in terms of sphericity and water resistance. Assessing a manufacturer's investment in R&D and their commitment to innovation indicates their future-readiness and ability to adapt to evolving market demands, such as sustainable materials or smart ball technology. Production Capacity and Scalability are paramount for B2B clients requiring large or fluctuating order volumes; a manufacturer's ability to ramp up or scale down production efficiently directly impacts lead times and stock management for the buyer. Coupled with this, robust Quality Control Protocols throughout the entire production cycle, from raw material inspection to final product testing, are non-negotiable. This includes detailed checks for weight, circumference, rebound, water absorption, and pressure retention, ensuring every soccer ball 5 or soccer ball 4 leaving the factory meets the agreed-upon specifications. After-sales Support and Warranty provide crucial peace of mind, demonstrating a manufacturer's confidence in their product and commitment to long-term partnerships. This includes clear warranty terms against manufacturing defects and responsive customer service for any post-delivery issues. Finally, Pricing Structure and Ethical Sourcing/Labor Practices must be evaluated; while competitive pricing is essential, it should not come at the expense of fair labor practices or environmental responsibility, which increasingly influence brand perception and consumer choice. Beyond standard production, reputable manufacturers excel in Bespoke Customization Solutions, allowing B2B clients to differentiate their offerings and cater to specific market niches. This level of customization can include Custom Branding, where logos, color schemes, and specific graphics are expertly integrated onto the ball panels. This is especially vital for sports clubs, corporate sponsors, or promotional campaigns aiming to maximize brand visibility on soccer balls. Material Specification is another key customization point; clients can choose specific grades of PU or PVC, allowing for optimization between softness, durability, and cost for a pu soccer ball or a pvc soccer ball designed for particular uses. Size and Weight Variation are standard customization options, including not just the ubiquitous soccer ball 5 and soccer ball 4, but also futsal balls, mini balls, and specialized training balls with altered weight distribution. Clients can also influence Panel Design, choosing traditional 32-panel layouts or modern fewer-panel constructions, which impacts the ball's aerodynamics and aesthetic appeal. Even the Valve Type can be specified for optimal air retention or ease of inflation, while various Packaging Options cater to different retail or shipping requirements, from bulk packaging to individual display boxes. The product "Factory Directly Wholesale Custom Soccer Ball Most Popular Size 4 Rubber Football Foot Ball" exemplifies a manufacturer's ability to offer tailored solutions, specifically catering to the popular size 4 for youth and demonstrating flexibility in material (rubber football) and wholesale custom branding. Choosing a manufacturer that embodies these attributes ensures not just the acquisition of high-quality soccer balls but also the establishment of a robust, reliable, and mutually beneficial supply chain partnership that can evolve with market demands and deliver consistent value.

Illustrative Application Cases and Customer Success Stories

Real-world application cases underscore the tangible benefits of strategic soccer ball procurement for B2B entities, demonstrating how tailored solutions and reliable manufacturing partnerships translate into operational success and enhanced client satisfaction. These scenarios provide invaluable insights into the experience and authoritative capabilities of a supplier.

Case Study 1: Empowering Youth Development for "Global Soccer Stars Academy"

Global Soccer Stars Academy, a leading youth football training institution with over 5,000 registered players across multiple age groups, faced a recurring challenge: the rapid wear and tear of training soccer balls. Their previous supplier offered cost-effective but low-durability pvc soccer balls, leading to frequent replacements and inflated operational expenses. Recognizing the need for a more sustainable solution, the Academy partnered with a reputable manufacturer specializing in robust, high-performance training soccer balls. After a detailed consultation, the manufacturer proposed a bulk order of machine-stitched pu soccer ball variants, specifically tailored for intensive daily training. This included a mix of soccer ball 4 for their U8-U12 programs and soccer ball 5 for their U13+ squads, all featuring reinforced linings and abrasion-resistant outer casings. The Academy reported a 40% reduction in annual ball replacement costs within the first year, alongside overwhelmingly positive feedback from coaches and players regarding the consistent touch and longevity of the new balls. Coaches noted that the consistent feel of the pu soccer ball significantly aided skill development, reducing variations in ball response. This case highlights the long-term cost-effectiveness and performance benefits of investing in quality soccer balls tailored to rigorous training environments, moving beyond initial price point considerations to focus on total cost of ownership and developmental impact. The partnership solidified due to the manufacturer's ability to provide not only a durable product but also technical expertise in material selection and construction for specific training needs.

Case Study 2: Elevating Brand Visibility for "SportFusion Retail Chain"

SportFusion, a prominent sports equipment retail chain operating across North America, sought to enhance its exclusive private label offering for soccer balls to compete with major brands. Their objective was to introduce a premium line of soccer balls 5 and soccer ball 4 that combined aesthetic appeal with professional-grade performance, targeting serious amateur players and local league teams. They partnered with a manufacturer renowned for its advanced thermal bonding technology and extensive customization capabilities. The manufacturer worked closely with SportFusion's design team to create a unique 14-panel thermal-bonded soccer ball featuring a custom surface texture for enhanced grip and a proprietary vibrant graphic design. Crucially, these balls met IMS (International Matchball Standard) quality parameters, ensuring consistent performance. The product launch was a resounding success, with SportFusion reporting a 25% increase in market share for their private label soccer balls within six months. Customer reviews frequently praised the ball's true flight, consistent bounce, and premium feel, often comparing it favorably to top-tier brands. This success story demonstrates how bespoke customization, combined with cutting-edge manufacturing technology (thermal bonding for a smooth, high-performance soccer ball), can create a compelling product that not only strengthens a retail brand's market position but also builds consumer loyalty through superior product experience. The manufacturer's adherence to stringent quality controls, ensuring every soccer ball delivered was consistent in its technical specifications, was a cornerstone of this success, providing SportFusion with a reliable, high-quality product for their discerning customer base.

Case Study 3: Optimizing Logistics and Supply for "Community Sports Foundation"

The Community Sports Foundation, a non-profit organization providing equipment to underprivileged schools and community centers, faced logistical hurdles and inconsistent product quality with their previous multi-vendor procurement strategy for soccer balls. They needed a reliable single-source supplier capable of providing large volumes of durable, cost-effective soccer balls suitable for varied playing conditions, from grass fields to rough concrete. They collaborated with a manufacturer known for its high-volume production capacity and robust pvc soccer ball offerings. The manufacturer provided a consistent supply of durable machine-stitched pvc soccer balls and rubber footballs, specifically designed to withstand abrasive surfaces and rough handling. They also streamlined the logistics, offering consolidated shipments directly to regional distribution hubs, significantly reducing the Foundation's administrative burden and shipping costs. The Foundation praised the manufacturer for their reliable delivery schedule (often within 30-45 days for large custom orders, much faster for standard stock items) and the consistent quality of the soccer balls, which minimized issues like premature deflation or panel detachment. The ability to receive a mix of soccer balls 5 and soccer ball 4 with uniform quality and predictable delivery allowed the Foundation to serve more communities effectively. This case exemplifies how a manufacturer's operational excellence in production, quality control, and logistics can profoundly impact a B2B client's ability to fulfill its mission, highlighting the importance of a comprehensive partnership that extends beyond just product features to encompass the entire supply chain.

Ensuring Trust and Addressing Common Inquiries

Establishing trust is paramount in any B2B relationship, especially when procuring critical sports equipment like soccer balls. A transparent and reliable supplier will not only meet product specifications but also provide robust support and clear communication channels. Here, we address common inquiries and outline the commitments that build enduring trust for B2B buyers.

Frequently Asked Questions (FAQ):

Q1: What is the typical lifespan of a high-quality soccer ball in a B2B context?

The lifespan of a soccer ball varies significantly based on its construction, materials, and usage intensity. A premium thermally-bonded pu soccer ball designed to FIFA Quality Pro standards can last several seasons in a professional training environment with proper care, enduring thousands of kicks. Conversely, a machine-stitched pvc soccer ball used intensively on abrasive surfaces might last one to two seasons. Our "Factory Directly Wholesale Custom Soccer Ball Most Popular Size 4 Rubber Football Foot Ball" for instance, leveraging durable rubber, is designed for extended recreational and training use. Proper inflation and storage significantly extend life.

Q2: How do FIFA Quality standards impact ball performance and procurement decisions?

FIFA Quality standards (FIFA Quality Pro, FIFA Quality, IMS) are critical benchmarks that ensure a soccer ball meets specific performance criteria, including weight, circumference, sphericity, water absorption, and rebound. For B2B procurement, these certifications guarantee consistency and reliability. Procuring FIFA-certified soccer balls 5 for competitive play or FIFA-approved soccer ball 4 for youth academies ensures that the equipment meets international playing standards, impacting player development, fairness of play, and ultimately, your organization's reputation.

Q3: What are the key differences between a pu soccer ball and a pvc soccer ball, and which is better for bulk orders?

A pu soccer ball typically offers a softer touch, better elasticity, superior grip, and higher water resistance, making it ideal for high-performance match play and premium training due to its close resemblance to natural leather. A pvc soccer ball, while generally less soft, excels in durability, abrasion resistance, and cost-effectiveness, making it an excellent choice for intensive training, recreational use, and large-scale bulk orders where ruggedness and budget are primary concerns. The "better" choice depends entirely on the intended application and budget, with manufacturers often advising on the optimal material for specific use cases.

Q4: Can we order custom-designed soccer balls 5 and soccer ball 4 with our branding?

Absolutely. Customization is a core service for B2B manufacturers. We offer comprehensive customization options, including bespoke branding (logo printing, color schemes), specific material choices (e.g., specific PU or PVC grades), various panel designs, and different sizes (e.g., soccer balls 5 for adults, soccer ball 4 for youth and futsal). This enables businesses, sports organizations, and event organizers to create unique soccer balls that align perfectly with their brand identity or specific event needs. Our process involves close collaboration from design to production to ensure your vision is realized.

Q5: What is the standard delivery lead time for bulk orders of soccer balls?

Delivery lead times for bulk orders of soccer balls can vary depending on the order volume, customization complexity, and current production schedule. For standard, non-customized stock items, lead times can be as short as 7-15 days. For custom-designed bulk orders, particularly those requiring specific material sourcing or intricate printing, typical lead times range from 30 to 45 days after design approval and deposit. We maintain transparent communication throughout the production cycle, providing regular updates to ensure timely delivery and efficient supply chain management for our B2B partners.

Q6: What warranty or after-sales support is provided for bulk soccer ball purchases?

We stand by the quality of our soccer balls with a comprehensive warranty against manufacturing defects, typically covering a period of 6-12 months from the date of purchase, depending on the product type and materials. Our commitment extends beyond delivery; we offer dedicated customer support to address any post-purchase inquiries, quality concerns, or logistical questions. Our internal quality control processes adhere to stringent standards, often including ISO guidelines for manufacturing, ensuring that each soccer ball is rigorously inspected before shipment, minimizing the likelihood of issues and reinforcing our trustworthiness as a long-term B2B partner.

Concluding Insights and Industry Outlook

In summation, the strategic procurement of soccer balls for B2B entities necessitates a comprehensive understanding of evolving industry trends, intricate technical specifications, and a manufacturer's capacity for customization and reliability. As highlighted throughout this discourse, the choice between a robust pvc soccer ball and a responsive pu soccer ball, or the precise specifications for a soccer ball 5 versus a soccer ball 4, directly impacts performance, durability, and cost-effectiveness across diverse applications, from elite competitive play to extensive grassroots training programs. The global market continues its trajectory of innovation, driven by advancements in material science—seeking more sustainable and recycled components—and the integration of smart technologies that offer unprecedented data insights into player performance. Furthermore, the increasing global participation in football necessitates scalable production capabilities and stringent quality assurance protocols to meet sustained demand for all types of soccer balls, while maintaining adherence to international standards like those set by FIFA. For B2B decision-makers, prioritizing partnerships with manufacturers who not only possess advanced technical expertise and state-of-the-art production facilities but also demonstrate unwavering commitment to quality, ethical practices, and proactive customer support is paramount. Such collaborations ensure a consistent supply of high-performance, regulation-compliant soccer balls that uphold brand integrity, enhance end-user satisfaction, and contribute to the growth and development of the sport globally. The longevity and playability of a soccer ball are not merely features; they are crucial determinants of value for organizations investing in sports equipment, influencing everything from training efficacy to spectator experience. Therefore, a forward-looking procurement strategy will consistently seek out manufacturers capable of delivering not just a product, but a comprehensive solution that anticipates market needs and adapts to future technological and material innovations, solidifying a competitive edge in a dynamically evolving industry. Navigating these complexities effectively positions B2B clients at the forefront of the sports equipment market, ready to capitalize on new opportunities and cater to the ever-growing passion for football.

References: